For this week’s assignment I decided to work on my final project for ICM/ Pcomp and build an enclosure for it, the fabrication part of the project I need to create 36 holes to embed 36 female inputs for an audio jack. I decided to build a wooden frame with tick solid wood and to laser cut the cover that would have the holes on it.

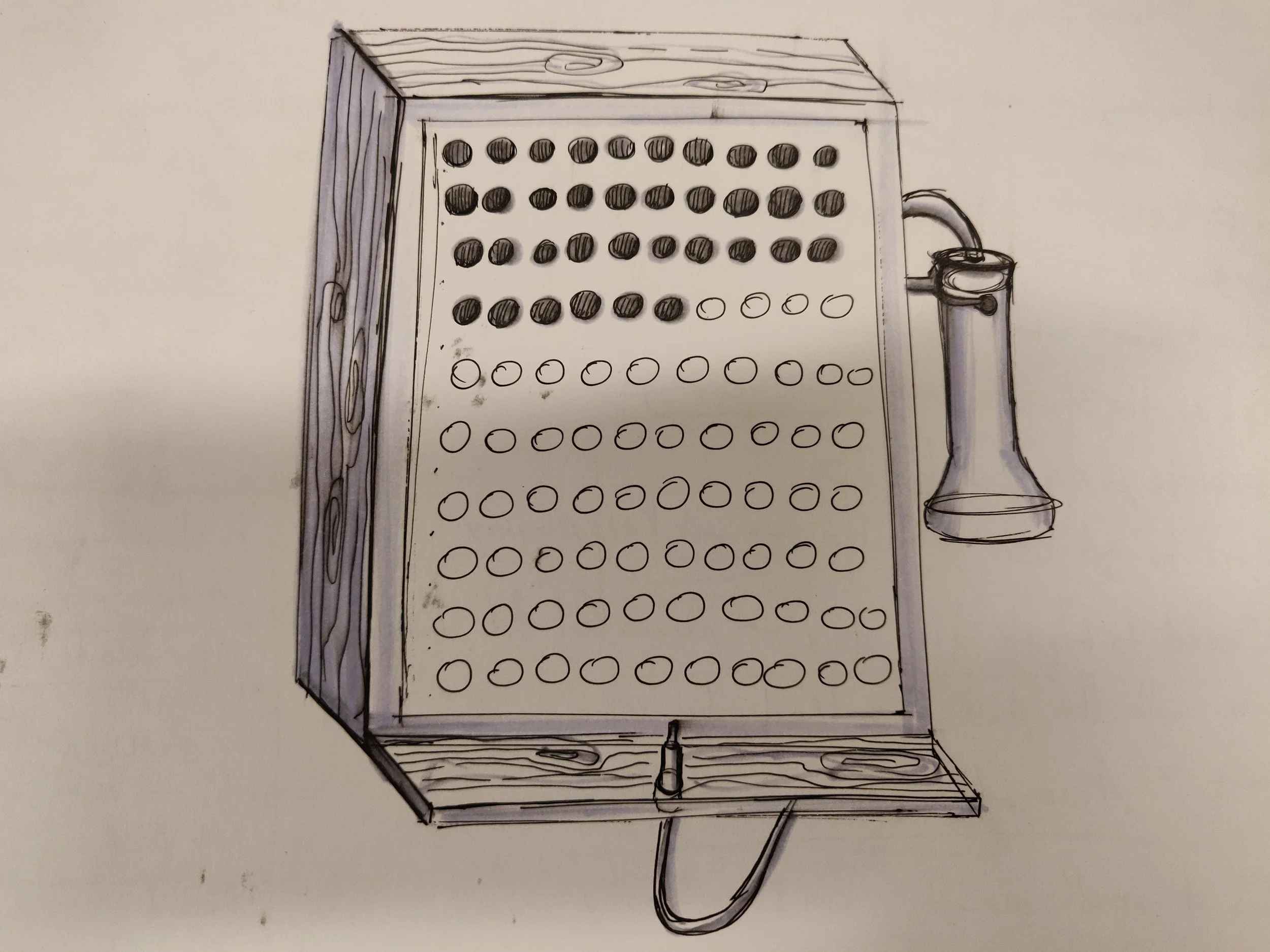

First sketch of enclosure

I started by cutting 45 degree angles on my recycled wood, I measured the sides and tried to calculate very well measured angles so that I could then ensemble them as a frame.

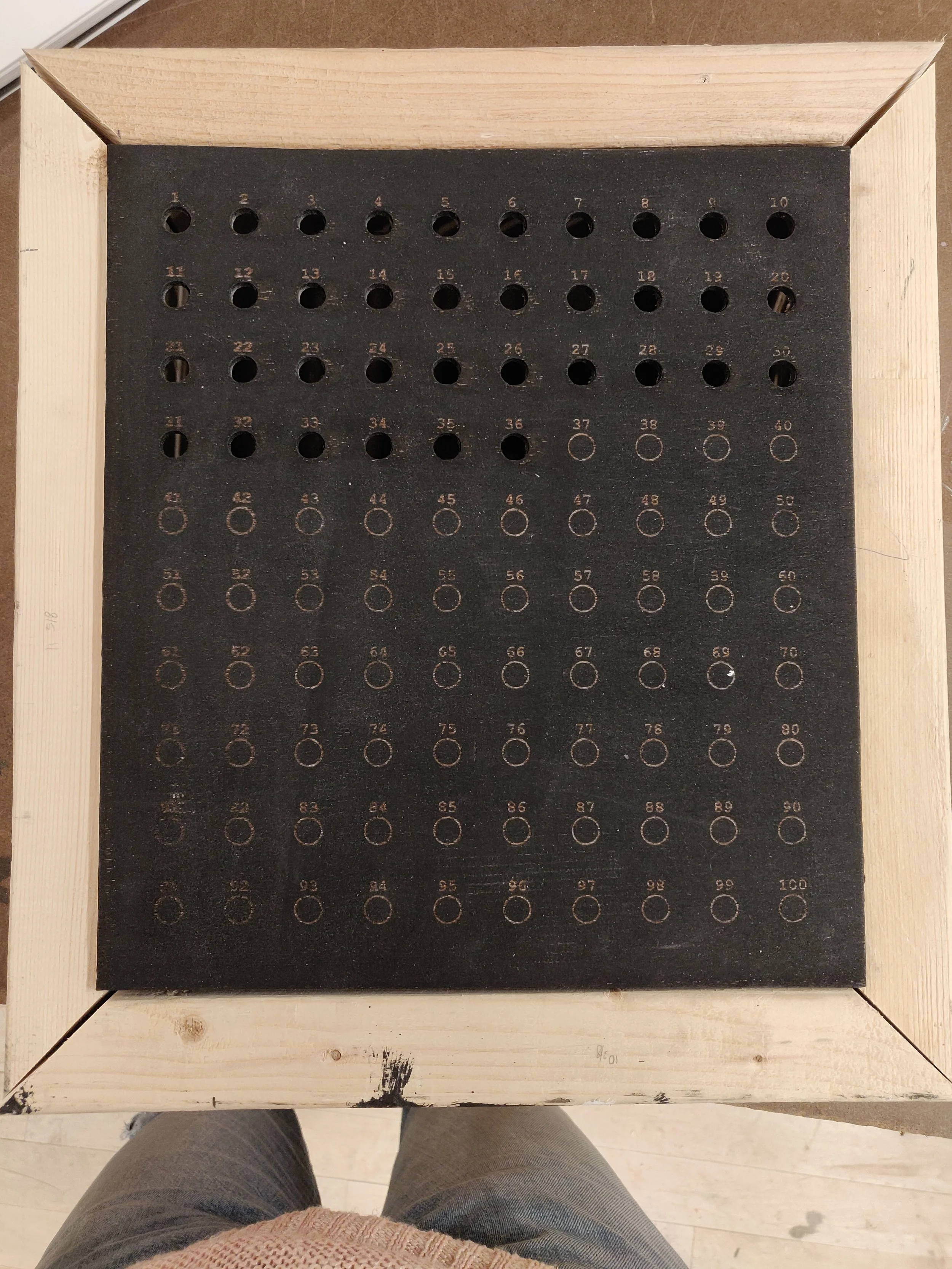

I was able to fabricate 4 pieces with 45 degrees. I developed the first test of the cover in recycled pre painted wood, however since it was bend I had to create a second piece changing the material for a flatter one so that the laser cutter would work in a better way.

Assembly of the frame

I ensemble the four pieces of wood together with L shape mechanical drilled joints to ensure the stability of the structure.

L shape internal support to hold together the frame

Finalized wooden frame

The second test of the cover was developed in the laser cutter, I edged the numbers and the circles that do not need a hole and I also included in the Illustrator file the cut of the circles for the female inputs and the holes for the screws so that I could ensemble the cover to the frame in a very robust way.

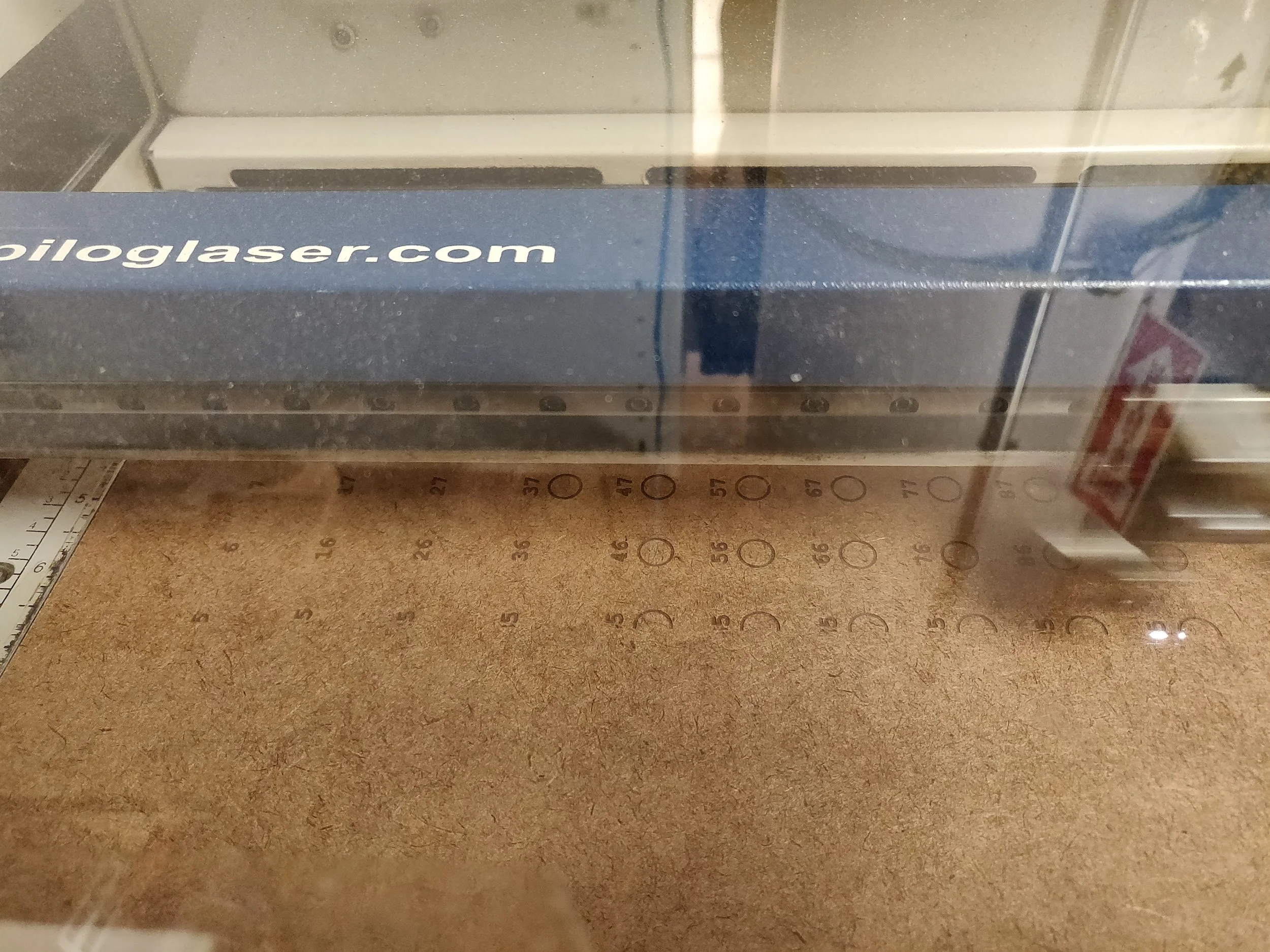

Laser cutting second version of the top

Drilling holes to support the top to the frame

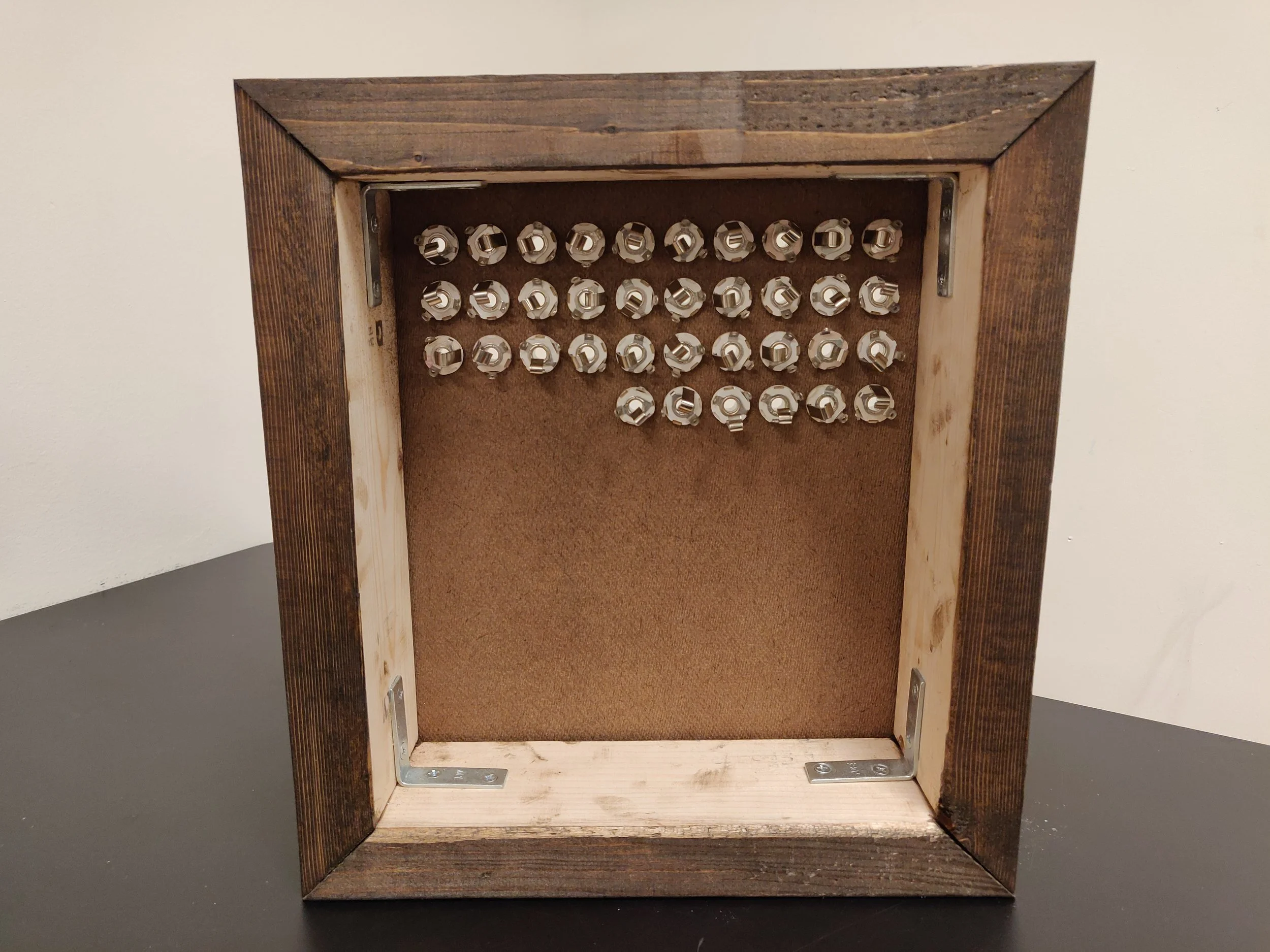

The final step consisted in putting together all the 36 female inputs for the audio jack on with the cover laser cutter piece.

Placing the 36 inputs

Placing the 36 inputs

Final enclosure in the back

The final result is an enclosure that will be used for my final ICM and Pcomp project, the fabrication was made in a very robust and strong way thinking in advance about the user interaction and the manipulation that they might give to my piece. Since the audio jack will be changed from one female input to another multiple times, I needed to make sure that the structure and functionality of the piece remain good throw the entire time that it is going to be displayed to the users.

Final enclosure design