For this week’s assignment I had to use a laser cutter in order to create a product. I decided to start by doing research about interesting shapes for maps made with such technology and I got inspired by the following products that I found online:

Moodboard and inspiration

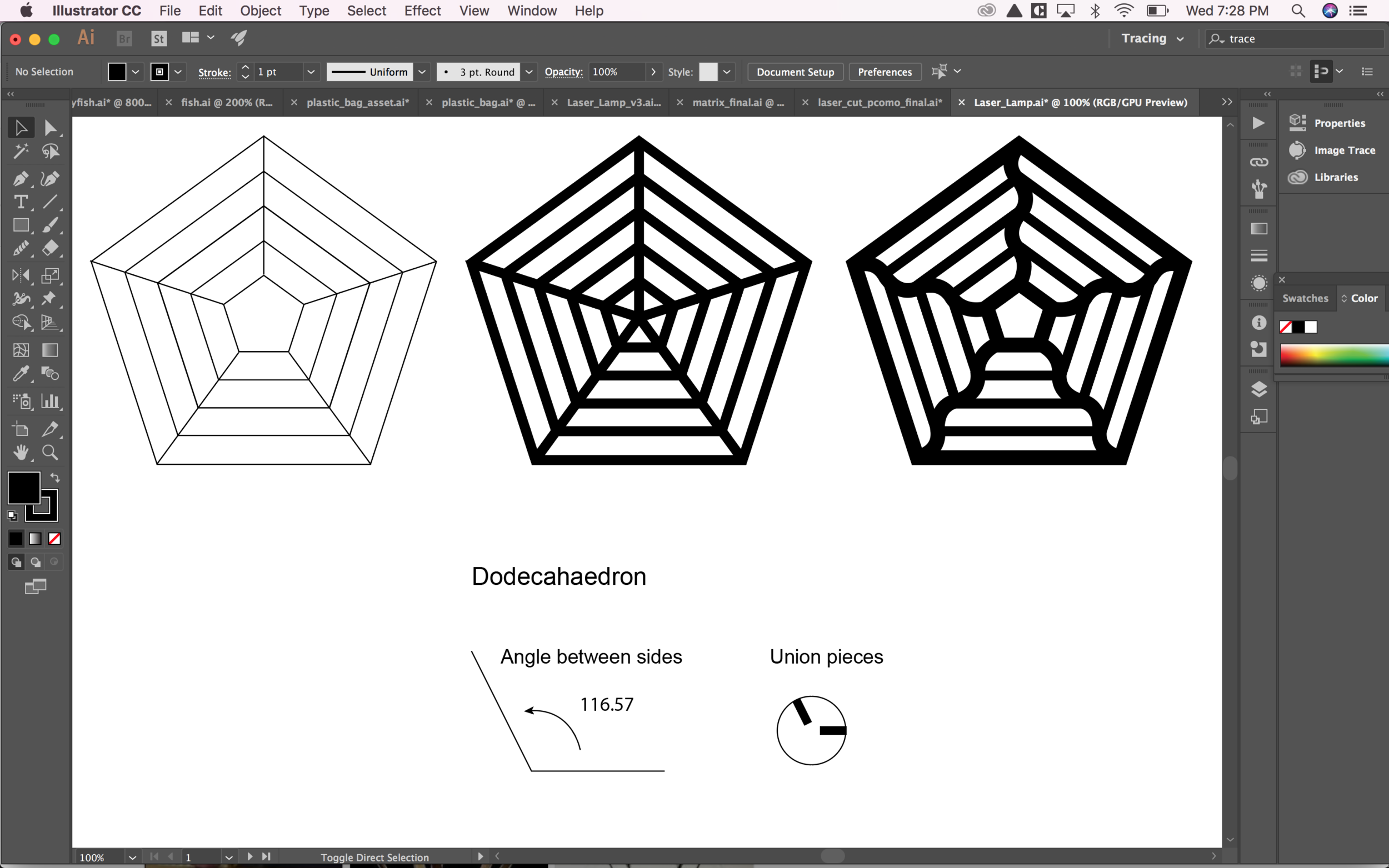

I decided to work with a dodecahedron, a 12 pentagonal faces 3d structure that would allow me to design an interesting pattern to be cut in order to let the light pass. I experimented with different shapes but decided to use more geometric (instead of fractals that was my first option) due to the complexity level and the time that it would take to laser cut such shapes.

Vector and pieces design

The second phase of the design consisted in figuring out a way to fit the pentagons by doing circles with the material width (3mm) that would be connected to each one of the sides of the pentagon. I realized I could have search online for a template that contained this kind of union but I decided to design it myself based on the needs that I had. That gave me the freedom to also change the design of the bottom pentagon so that it could have the hole to introduce the bulb in the future.

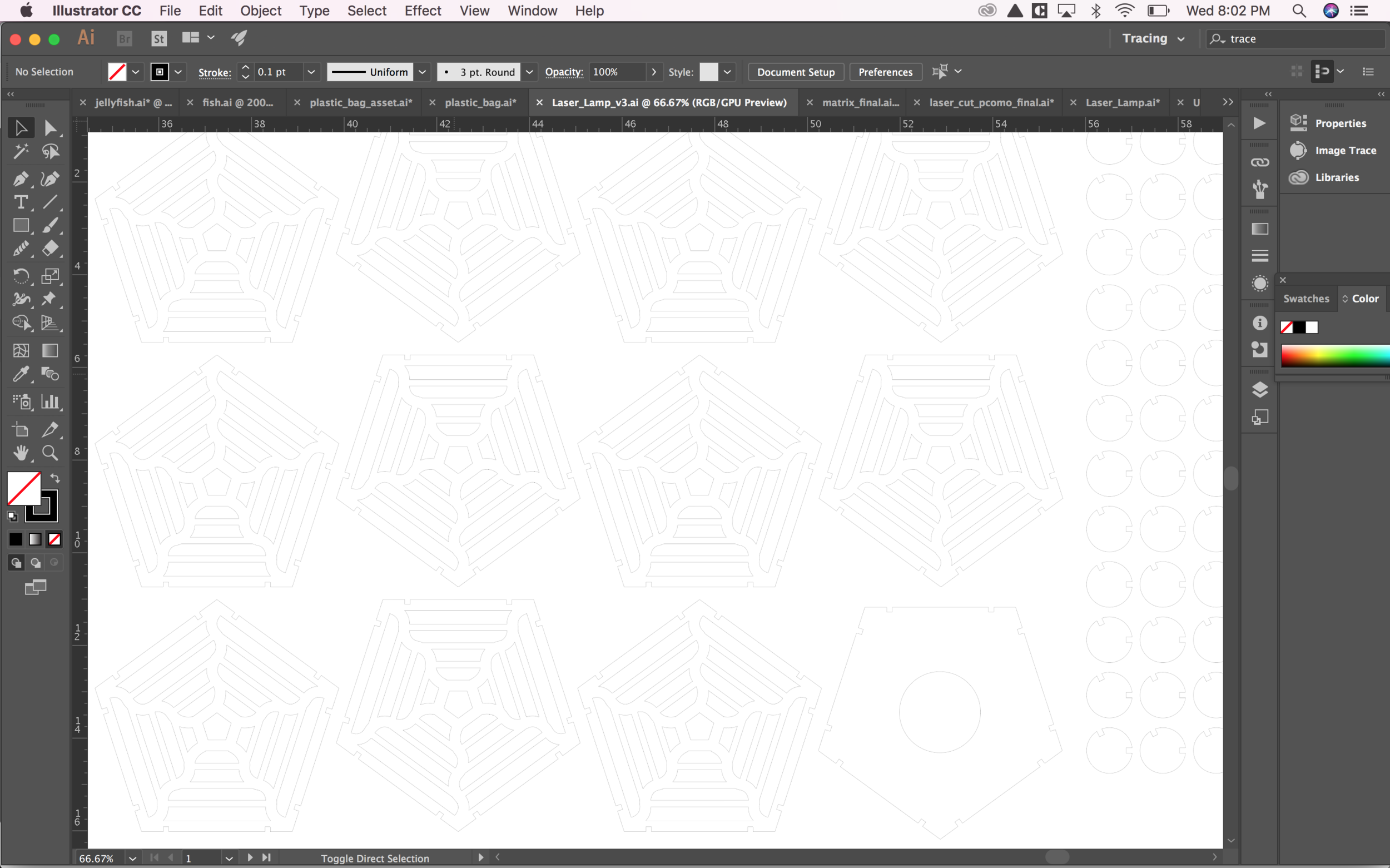

Asset preparation

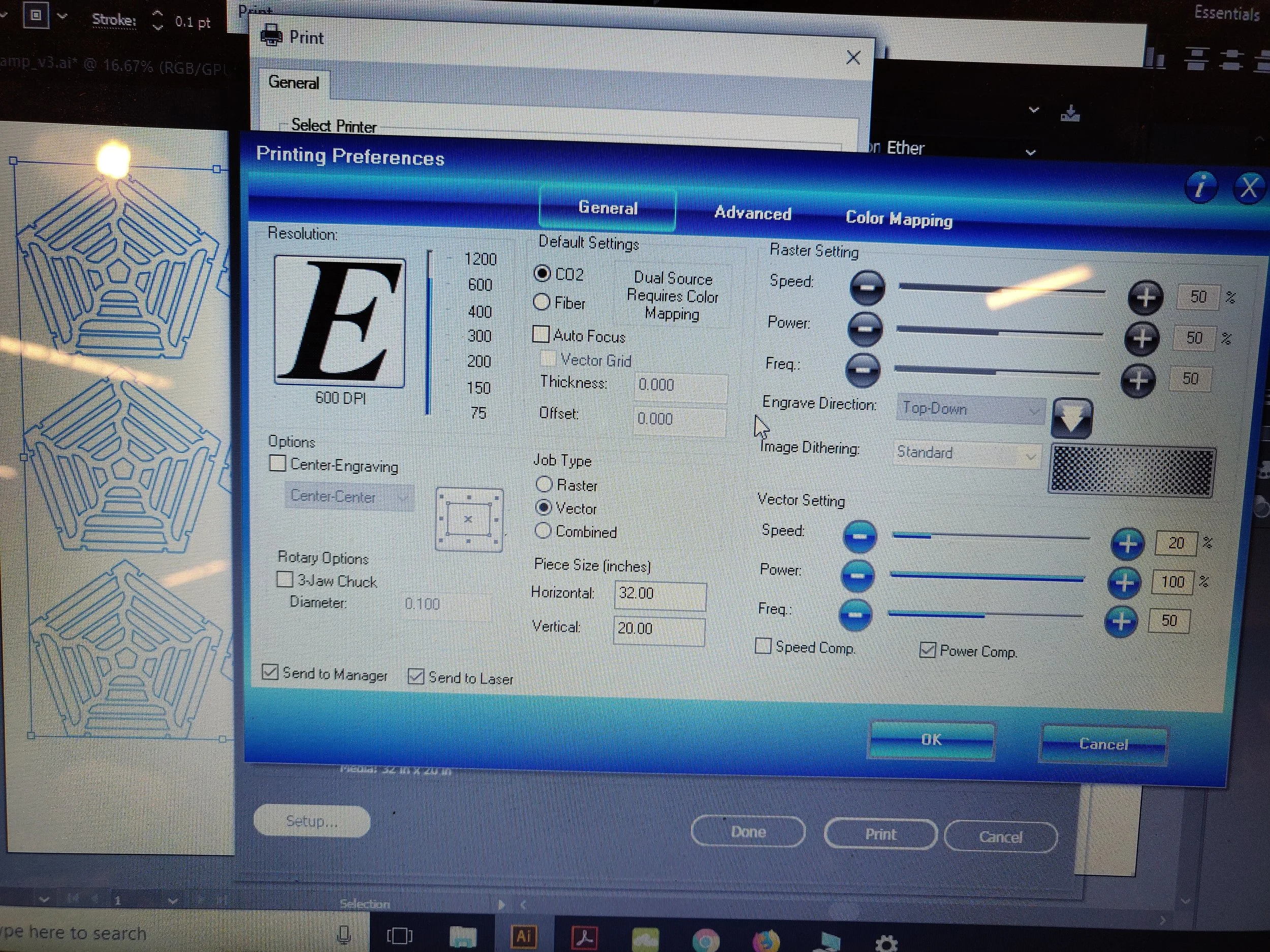

I decided to use the settings for wood since the ones for cardboard might not be powerful enough to cut all the way through. I had to deal with the fact that my material had glue in between the layers therefore that represented a challenge that I had to deal with while selecting the settings for the printer.

Laser cut settings

I realized that my pieces were a little bit burned out but that was the only way that I found in order to cut all the way throw the material. Also the time represented a challenge since I spent two hours cutting pieces, I had to cut 60 circular pieces and 12 pentagonal pieces.

Laser cutting process

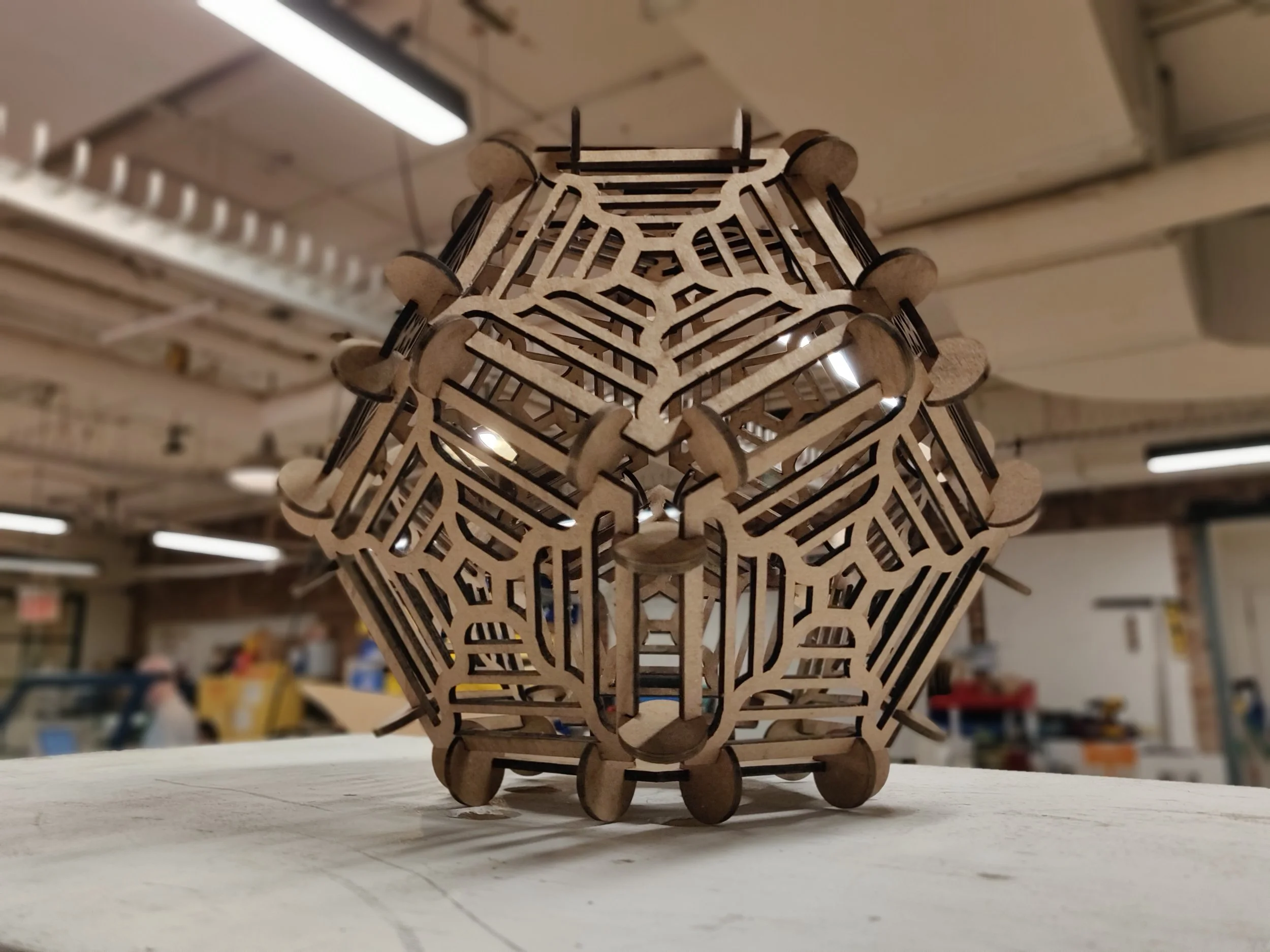

The assembly process was also very tricky since I had to be holding together the circles and the pentagons with each other, but in the moment that I started to close it with the last pieces they started to hold each other together which gave me reaffirmation that the measures that I stablished in the design of my pieces was correct.

Assembly of pieces

The final result is a laser cut lamp that doesn’t need glue to stay together and instead uses physical unions that hold each other with the pressure and the friction generated from the same material. The shape of the faces allow the light to go throw the holes, generating interesting patterns of light in the space that occupies.

Final Design